Shaft couplings are very important components of machinery that connect rotating shafts. The EK shaft coupling bearing (ลูกปืนจับยึดปลายเพลา EK, which is the term in Thai) has unique advantages for various applications. Knowing the key features of these parts will help you to make decisions for your mechanical systems. Read on to learn them.

Superior Design for Enhanced Performance

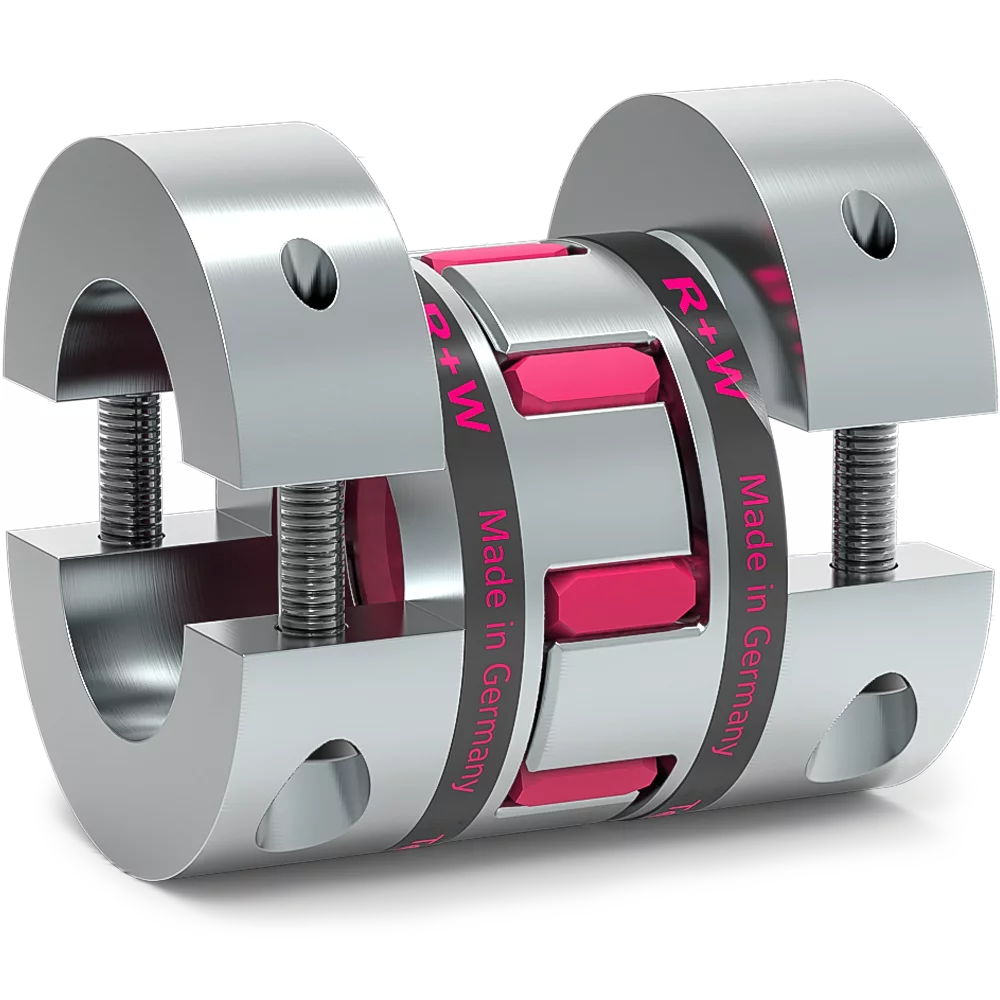

EK shaft coupling bearing design is focused on functionality and durability. Precision engineering is used in these bearings to align rotating components perfectly. Thanks to their construction, they vibrate very little during operation. The materials used are chosen specifically to resist wear and tear. This thoughtful design results in your machinery having a longer operational life.

Excellent Load Capacity

EK shaft coupling bearings can handle axial and radial loads well. Because of this dual load capacity, it is designed for use in demanding industrial applications. The internal structure of the bearing distributes the forces evenly over its components. It also prevents premature failure even under heavy loads. The lifespan of connected machinery is directly dependent on the load-bearing capability.

Reduced Noise and Vibration

These bearings are known to reduce operational noise in rotating machinery. The vibration dampening properties help to reduce the running noise of equipment. This reduction in noise makes the workplace more bearable for operators. This also reduces wear on connected components due to lower vibration levels. Users report that installing these specialised bearings makes the machine quieter.

Temperature Resistance

EK shaft coupling bearing can bear a wide temperature range of materials. They are suitable for cold and hot operating environments. The bearing maintains its performance even as temperatures vary. The design specifications include thermal expansion. This temperature versatility expands the potential applications significantly.

Easy Installation and Maintenance

An EK shaft coupling bearing installation requires few specialised tools. The simple installation process reduces the installation time. Maintenance needs are also kept to a minimum through clever design choices. Access points are easily reached when maintenance is required. There is reduced downtime and maintenance costs due to the ease of handling.

In conclusion, EK shaft coupling bearing boasts some very excellent features that are useful in many mechanical applications. Reliable performance is achieved with their superior design and load capacity. Their practical value is increased by the temperature resistance and easy maintenance. These bearings reduce noise and vibration in industrial machinery.

This allows you to make informed decisions with regard to your mechanical systems. Take into account the specific advantages that these specialised bearings offer for optimal machinery performance and reliability.